- 0086-0576-84399766

- vip@yinglangmold.com

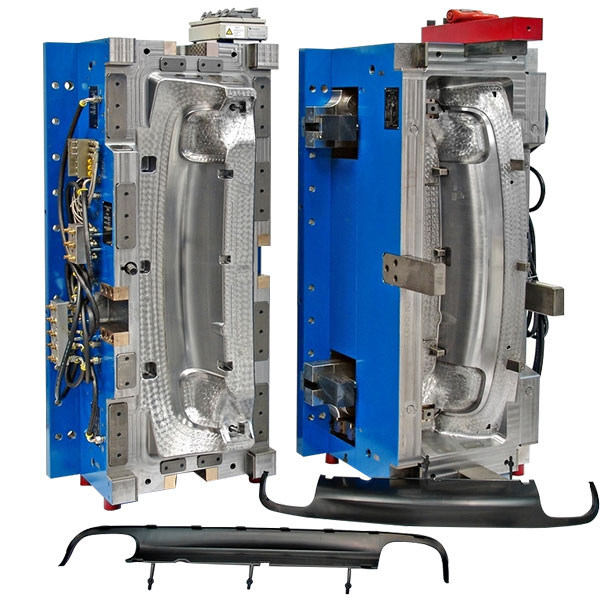

Taizhou Huangyan Yinglang Mould Co., Ltd. is a professional manufacturer of Auto Parts Mould. Our services include design, mold making, product injection molding, assembly and other follow-up processes.

Core cavity material selection: (according to customer's needs), our professional advice: Pre-hardened steel: P20 (1.2311), P20+Ni...etc; Hard steel: H13 (1.2344) / NAK80...etc. Stainless steel: ASSAB Stavax …Wait

Formwork selection: (according to customer's needs), we recommend customers to use Longji standard formwork, the material is S50C or P20

Core cavity hardness requirements: pre-hardened steel: HRC 30~32+-1* heat-treated steel: HRC 50~52+-1*

Core release: (according to product requirements). Commonly used methods: motor, cylinder, stripper, thimble, etc.

Mold accessories: DME / HASCO standard parts.

Die life: (depending on material grade), ideally, 1. Pre-hardened steel, minimum. 20~300,000 die; 2. Hard/heat treated steel: 60~800000 die. 3. Stainless steel: 1000000 die.

Production: Injection molding production, follow-up process.